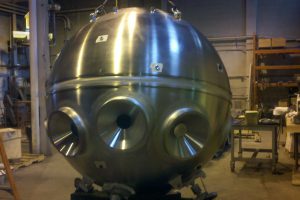

Diving Bell Inspection

Industrial Measurement Solutions LLC was requested to inspect the outside diameter of a diving bell both before and after heat treatment was performed. The bell measured 90″ in diameter, and weighed approximately 18,000 lbs. By mapping out any deviations in the sphere both before and after heat treatment, we could investigate if the heat-treating process had any effect on the roundness of the spherical diving bell.

Upholding a tightest tolerance of (+/-) .020″, we performed on-site inspections at 250 specific locations around the diving bell, in order to accurately map out any roundness deviations. Before heat treatment, the sphere measured .043″ form error. After heat treating, the diving bell measured .041″. Therefore, by using our superior diving bell inspection technology, we discovered an average standard deviation of just .0012″ at the 250 points after the part was heat treated.

This Diving Bell Inspection project is one of many quality jobs completed by Industrial Measurement Solutions. If you have a similar need, please contact us for more information at 419-889-3087.